- No Results

- Global

-

Australia

-

Austria

-

Azerbaijan

-

Brazil

-

Belgium

-

Canada

-

Chile

-

China

-

Costa Rica

-

Croatia

-

Czech Republic

-

Denmark

-

ESTONIA

-

Finland

-

France

-

Germany

-

Hong Kong

-

Hungary

-

India

-

Italy

-

Ireland

-

Japan

-

Korea

-

Latvia

-

Lithuania

-

Malaysia

-

Mexico

-

Morocco

-

Netherlands

-

New Zealand

-

Norway

-

Philippines

-

Poland

-

Portugal

-

Romania

-

Singapore

-

Slovakia

-

Slovenia

-

Spain

-

Sweden

-

Switzerland

-

Taiwan

-

Turkey

-

United Kingdom

-

UNITED ARAB EMIRATES

-

United States

-

Vietnam

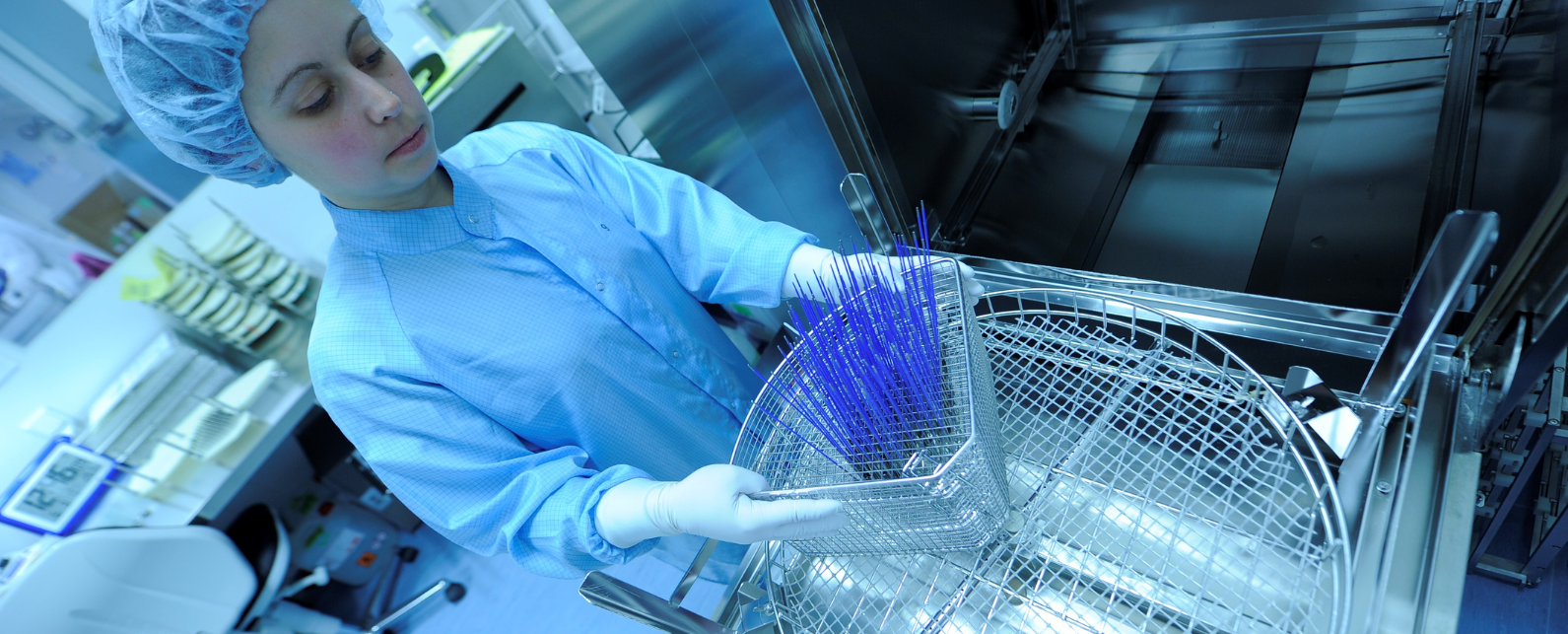

Cleaning

Contact usMedical device products must exhibit a defined and continuous state of cleanliness. The requirements for the cleanliness of medical products have steadily increased in recent years and form a safe starting point to achieve a sterile product.

The cleaning downstream process in manufacturing reduces microbiological contamination, known as bioburden, removes chemical contaminants from the manufacturing process and particulate contamination from general manufacturing, transport or storage processes.

Together with our customers, we develop cleaning procedures in accordance with product characteristics that meet the standards and legal requirements. Our validation team is at your disposal for planning and executing the cleaning validation process. Upon request, we can support you in analysing the pre-processing steps.

In order to be able to offer the optimal cleaning process, Eurofins Medical Device has extensive cleaning facilities:

- Vacuum extraction cleaning technology

- Cleaning and disinfection machines

- Vacuum drying

- Drying cabinets

- Drying with laminar flow

- Reverse osmosis system for water treatment

- Washing and disinfection machine, with and without detergent substances

- Rinsing bath with and without Isopropanol (IPA)

- Ultrasonic bath with and without IPA

- Wipe disinfection

- Plasma cleaning

The individual process steps from cleaning to packaging are carried out in ISO Class 7 and 8 clean rooms. Clean room production ensures a clean environment and a consistent hygiene status for the products right through to packaging. The clean rooms are regularly subjected to qualification and meet the relevant standards. The staff deployed in the clean rooms are specially trained for this work and are thus sensitised to the special requirements and correct behavior.