- No Results

- Global

-

Australia

-

Austria

-

Azerbaijan

-

Brazil

-

Belgium

-

Canada

-

Chile

-

China

-

Costa Rica

-

Croatia

-

Czech Republic

-

Denmark

-

ESTONIA

-

Finland

-

France

-

Germany

-

Hong Kong

-

Hungary

-

India

-

Italy

-

Ireland

-

Japan

-

Korea

-

Latvia

-

Lithuania

-

Malaysia

-

Mexico

-

Morocco

-

Netherlands

-

New Zealand

-

Norway

-

Philippines

-

Poland

-

Portugal

-

Romania

-

Singapore

-

Slovakia

-

Slovenia

-

Spain

-

Sweden

-

Switzerland

-

Taiwan

-

Turkey

-

United Kingdom

-

UNITED ARAB EMIRATES

-

United States

-

Vietnam

Search >>

Metallurgical Engineering & Characterisation

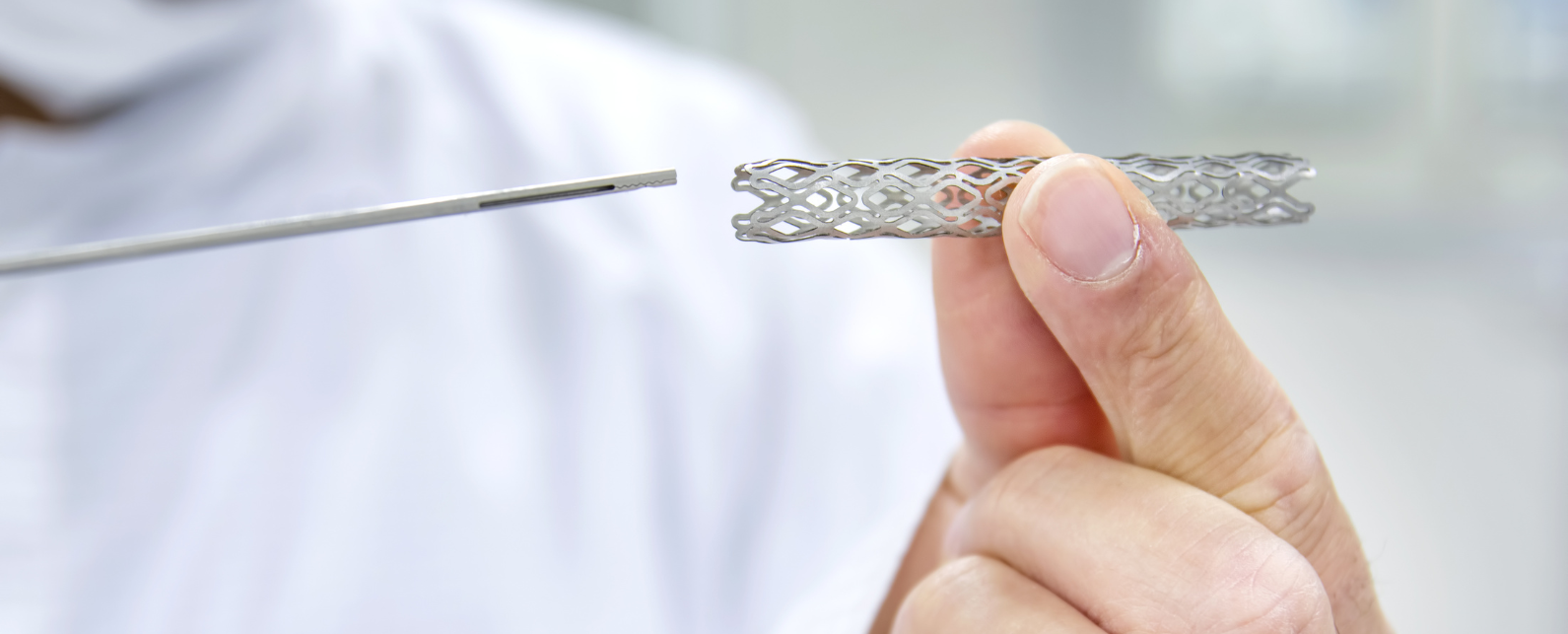

Contact usMetallurgical alloys are commonly used in medical device applications owing to their exceptional physical properties. In particular, a variety of implantable alloys (e.g., various stainless steels and nitinol) have been developed allowing for shape memory features and high fatigue applications. Expertise in metallurgical engineering is required to provide insight into materials properties and failure mechanisms.

Eurofins Medical Device Testing network of laboratories are equipped with state-of-the-art instrumentation for metallurgical characterisation:

- Elemental: ICP, XRF, EDS, GD-MS, SIMS

- Microscopy: SEM, TEM, FIB, AFM, OP, EBSD

- Surface: XPS/ESCA, TOF-SIMS, Auger

- Corrosion Testing: ASTM F2129

Choose Eurofins Medical Device Testing to help you with:

- Customised metallurgical engineering involving contaminant identification, failure analysis, materials identification, litigation support, materials and degradation.

- Identify corrosion resistance of a nitinol device.

- Assess the thickness and coverage of nitinol stent passivation layers.

- Embrittlement of metal parts.

- Solder joint failures.